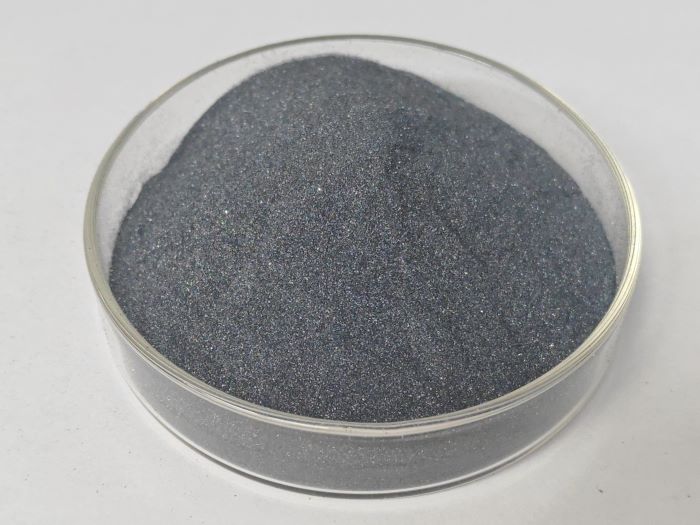

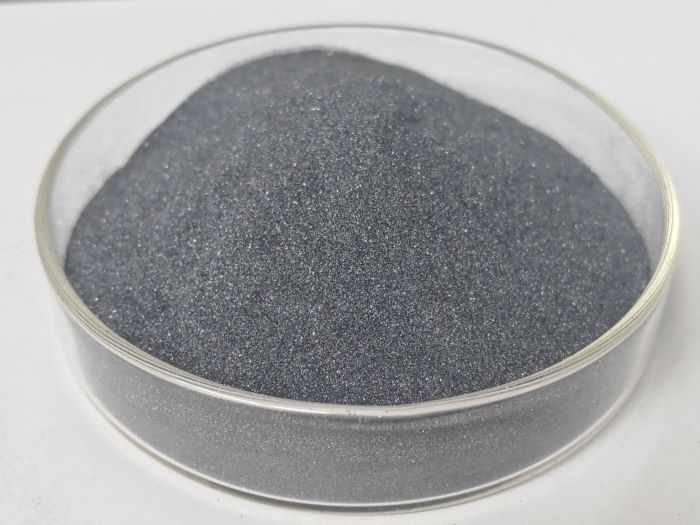

95% Black silicon carbide 53С 0-0.1mm

Product Introduction

95% Black Silicon Carbide 53С 0-0.1mm is a high-performance abrasive grain engineered for precision grinding, lapping, and finishing applications. This product is characterized by its exceptional hardness (9.25 on the Mohs scale), sharpness, and thermal conductivity.

Manufactured through an electric resistance furnace process, this grade consists of at least 95% silicon carbide (SiC). The « 53С » designation refers to a standardized particle size distribution, ensuring consistent and predictable performance. The fine mesh size of 0-0.1mm (or 0-100 microns) classifies it as a very fine powder, ideal for producing smooth surfaces and precise finishes.

Key Features & Advantages:

-

Extreme Hardness & Sharpness: Superior to traditional abrasives like alumina, it offers faster cutting rates and excellent material removal on hard, brittle materials such as tungsten carbide, ceramics, glass, and certain non-ferrous metals.

-

High Thermal Conductivity: Effectively dissipates heat from the grinding zone, reducing the risk of thermal damage to both the workpiece and tools.

-

Chemical Inertness: Suitable for use in various chemical environments without degradation.

-

Consistent Grain Size: The controlled 53С distribution guarantees uniform performance and repeatable results in manufacturing processes.

Primary Applications:

-

Precision Grinding & Lapping: Fine finishing of hard alloy components, technical ceramics, and optical lenses.

-

Abrasive Blasting: High-grade surface preparation and etching (using appropriate finer mesh specifications).

-

Refractory Additives: Enhances the strength and thermal shock resistance of advanced castables and ceramics.

-

Manufacturing of Coated Abrasives: Used in the production of fine-grit sandpaper and abrasive slurries.

-

Polishing Compounds: A key ingredient in pastes and suspensions for ultra-fine polishing.

This Black Silicon Carbide powder is the material of choice for industries demanding high precision, efficiency, and superior surface quality, including aerospace, automotive, optics, and semiconductor manufacturing.